I just purchased this car and I believe it has an air suspension issue

Active Suspension

ADJUSTMENTS

RIDE HEIGHT ADJUSTMENTS

Make sure the wheels and tires, tie rod ends, suspension joints and wheel bearings are free from damage, wear and free play.

Make sure there are no heavy objects in the vehicle.

With the engine running and all vehicle doors closed, make sure the air suspension is functioning and the vehicle height can be raised and lowered using the air suspension switch.

Drive the vehicle on to a flat, level surface and make sure the steering is in the straight ahead position.

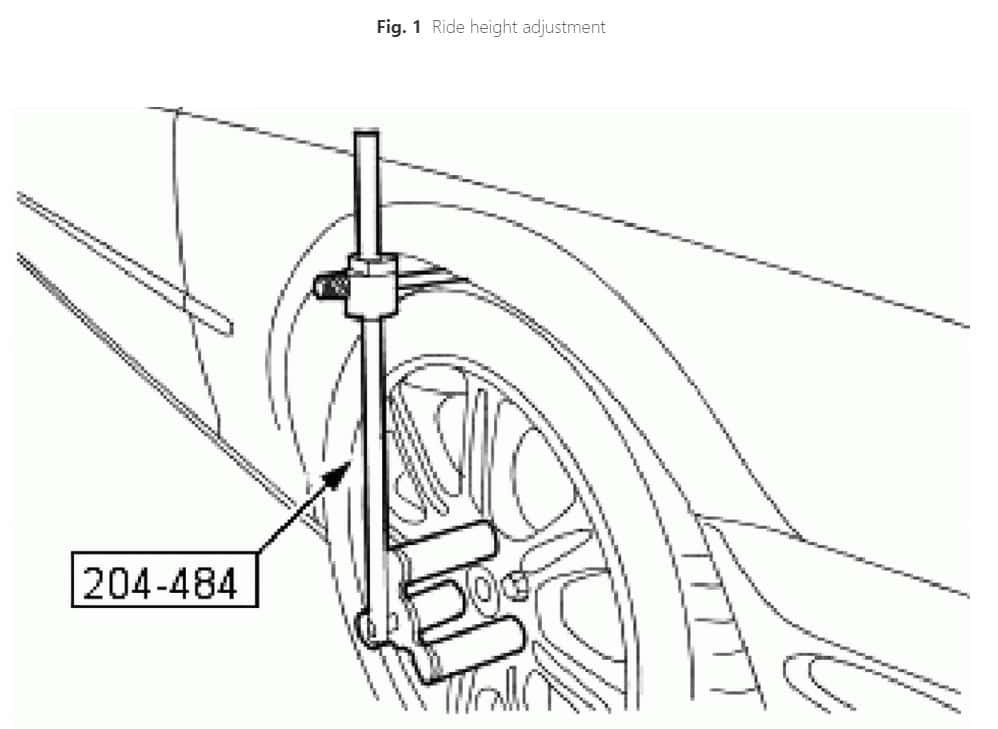

- Install Ride Height Measuring Tool No. 204-484 or equivalent.

- Make sure that ride height gauge is vertical as outlined, Fig. 1.

- Connect a suitably programmed scan tool or Jaguar approved diagnostic system to Data Link Connector (DLC) and follow manufacturers instructions.

AIR LEAKS

*Jaguar advises against using soapy water to find air hose leaks

Recommended leak detection spray is Nu-Calgon 4182-24.

Any spray used must have a corrosion inhibitor, and must not cause damage to paint work, plastics, metals or plastic pipes.

- Connect a suitably programmed scan tool or Jaguar approved diagnostic system to Data Link Connector (DLC) and follow manufacturers instructions to ensure that air suspension system is fully pressurized.

- Leak detection spray should be used to identify any suspected leaks. This procedure should also be used where any air suspension components have been disturbed.

- Clean area around suspected air leak.

- Spray around all air suspension components, working systematically until source of air leak has been found.

- If a new air suspension component is to be installed, and no air leaks have been detected, remove and discard new air pipe connections supplied with component.

- If any air suspension components are found to be leaking, repair is by replacement only. If an air leak from a pipe connector has also been identified, a new air pipe connector, must be installed.

- Only Jaguar approved connectors have been tested to meet manufactures, pressure and temperature specifications.

- Air pipes must only be cut using either hose cutter tool No. 204-494, available from SPX-LTD or hose cutter tool No. YA1000A, available from Snap-On Tools.

- If color coded markings adjacent to pipe connections are removed when cutting air pipes, cut end on air pipe must be clearly marked with a suitable colored tape or paint mark.

- If source of an air leak is found to be a pipe connection cut 5 mm (0.2 in) off end of pipe and install a new connector.

- If repair has been unsuccessful repeat above steps until air leak is rectified.

DESCRIPTION

VEHICLE DYNAMIC SUSPENSION

The vehicle dynamic suspension is a passive air suspension system providing vehicle levelling independent of load. The system also improves the drag coefficient by automatically lowering the vehicle for high speed driving.

When driving at high speeds, the air suspension system will lower the vehicle to improve aerodynamics and vehicle stability. The suspension will automatically return the vehicle to the normal ride height when the vehicle slows.

AIR SUSPENSION MODULE (ASM)

The air suspension module (ASM) controls the operation of the solenoids in the valve block. The front air springs are operated as a pair, the rear air springs are operated independently of each other. The ASM adjusts one axle at a time, for example, when lifting the vehicle the rear axle is controlled first; when lowering the vehicle the front axle is controlled first. This reduces headlamp glare during leveling operations.

The air suspension module (ASM) is accessed from the right-hand side of the vehicle, behind the back of the rear seat. The ASM can be recognized by the 4 individually colored connectors (gold, grey, yellow and pink) and the “WABCO” logo on the front of the module. ASM calibration is required when either a replacement module is fitted, or if any height sensors have been removed/refitted or replaced.

When installing a new air suspension module it will be necessary to configure the module into the customer mode using the Jaguar approved diagnostic system.

SUSPENSION HEIGHT SENSORS

Vehicles built before “December 2003” have four suspension height sensors which are mounted on the front and rear subframe assemblies, two front and two rear. Vehicles built after “December 2003” have only three (the right front sensor being deleted), although the functionality of the system remains the same. The suspension height sensors are linked to the suspension arms by drop link connections and secured by means of a spring clip.

There may be some early vehicles which will have four sensors fitted, but which have the three-sensor module, making the right front sensor redundant. To confirm the level of equipment, read the module part number from the special applications menu in configuration on the Jaguar approved diagnostic system. Part numbers before “BJ” are four sensor, while “BJ” and after are three sensor. If the Jaguar approved diagnostic system is not available, remove the rear seat and sound deadening and read the part number from the module.

AIR SPRINGS

Two derivatives of the air spring are available, comfort and sport, the sport having slightly smaller working volumes for higher spring rates.

The air springs are complemented by two versions of damper assembly, passive and active.

SOLENOID VALVE BLOCK

The solenoid valve block contains five individual solenoid valves (one per air spring and one for the vehicle reservoir). A pressure sensor is incorporated into the solenoid valve block and monitors air spring and reservoir pressure. The solenoid valve block is mounted on isolators to reduce valve operation noise. Pipe connections are provided for the front and rear air spring assemblies and also the reservoir and compressor. The compressor to valve block port and the rear air spring ports are 4 mm in diameter with the front air spring ports being 6 mm in diameter. Each of the solenoid valve block ports and air pipes are color coded (pink, blue, white, yellow, red and brown) for correct connection.

RESERVOIR

The reservoir has a volume of 4.5 liters with a maximum design pressure of 15 bar (218 psi). Dependent on load conditions, this store of reserve air is sufficient for two full lifts. The system automatically replenishes the reservoir by way of the compressor.

COMPRESSOR

The air compressor is located in the left-hand front wheel arch behind the bumper beam assembly. It contains an air filter, an integral regenerative air drier element plus an air exhaust solenoid valve. The compressor is isolated from the main body structure by 3 mounts, each incorporating a rubber bush and metal spring. The maximum pressure developed by the system is 15 bar (218 psi) with a compressor pressure relief valve fitted, set to relieve pressures above 17 Bar (247 psi). The compressor only operates whilst the engine is running. To guard against the compressor overheating the ASM may shut down the compressor to allow cooling to take place. Re-activation of the compressor depends on vehicle activity and is generally no longer than 120 seconds.

Air Suspension Inspection & Verification

- Verify customer concern.

- Confirm which, if any, warning lights and/or messages were displayed on instrument cluster display.

- Following messages can be displayed:

a. Vehicle too low.

b. Air suspension fault. - Visually inspect for obvious signs of mechanical or electrical damage, Fig. 28.

- If an obvious cause for an observed or reported concern is found, correct cause (if possible) before proceeding.

Air Suspension System Technical Bulletin

This Technical Bulletin has been issued to aid in the diagnosis of air suspension system faults.