A/C SYSTEM TROUBLESHOOTING

If an A/C system malfunction is suspected, check the following conditions:

- Check outer surfaces of radiator and condenser cores to ensure air flow is not blocked by dirt, leaves or other foreign material.

- Restrictions or kinks in condenser core, hoses or tubes.

- Blower motor operation.

- Refrigerant leaks.

- Check all air ducts for leaks or restrictions.

- Low air flow rate may indicate a restricted evaporator core.

- Compressor clutch slippage.

- Improper drive belt tension.

- Plugged accumulator or expansion (orifice) tube.

- Excessive moisture in the refrigerant system.

- Cooling fan, coolant thermostat and temperature door operation.

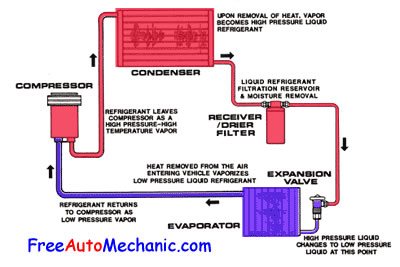

The diagram shows the flow of R-134a Freon in an automotive air conditioning system.

The freon is compressed and flows through the condenser where it is cooled into a liquid. The freon passes through the receiver/dryer to remove moisture. Once the freon leaves and enters the expansion valve/orifice tube The high pressure liquid becomes a vapor and is extremely cold as it passes through the evaporator and on to the compressor to repeat the cycle.

SEARCH AIR CONDITIONING

Common Air Conditioning System Problems

Only Hot air blows out the dash when I turn the Air Conditioning on.

This is usually caused by a failing or failed Blend Door Actuator. The Actuator is usually located deep in the dash and attached to the hot/cold blend door. The most common fix is to simply have it replaced. Of course this is after you have made certain that the rest of your air conditioning system is functioning properly. Listen for the AC Compressor to click in and out and feel the accumulator for cold temperatures. These are signs of a normal operating AC System.

No air coming from air conditioning vents

- Check the air conditioner fuse and replace as necessary.

- Air conditioner system discharged. Have the system evacuated, charged and leak tested by an MVAC certified technician, utilizing approved recovery/recycling equipment. Repair as necessary.

- Air conditioner low pressure switch defective. Replace switch.

- Air conditioner fan resistor pack defective. Replace resistor pack.

- Loose connection, broken wiring or defective air conditioner relay in air conditioning electrical circuit. Repair wiring or replace relay as necessary.

Air Conditioner blows warm air

- Air conditioner system is discharged. Have the system evacuated, charged and leak tested by an MVAC certified technician, utilizing approved recovery/recycling equipment. Repair as necessary.

- Air conditioner compressor clutch not engaging. Check compressor clutch wiring, electrical connections and compressor clutch, and repair or replace as necessary.

- Electronic Blend Door Actuator is not functioning which would only allow warm air to pass through vents. The AC lines going into the firewall would be cold if this is the case. Most common to replace actuator.

Water collects on the interior floor when the air conditioner is used

- Air conditioner evaporator drain hose is blocked. Clear the drain hose where it exits the passenger compartment.

- Air conditioner evaporator drain hose is disconnected. Secure the drain hose to the evaporator drainage tray under the dashboard.

Air conditioner has a moldy smell when used

- The air conditioner evaporator drain hose is blocked or partially restricted, allowing condensation to build up around the evaporator and drainage tray. Clear the drain hose where it exits the passenger compartment

How to recharge your air conditioning

Step by step instructions on how to recharge your air conditioning system yourself. Why not do it yourself, whatch how easy it is in the video. I made it while recharging the air conditioning system in my girlfriends 2004 Ford Ranger with R134a recharge kit.

Car AC Check - How to check car ac for manual air conditioning or climate control systems