Vacuum Diagrams

This is not an automated service. Each Diagram that is requested has to be hand selected and sent. As this is a free service it receives an overwhelming amount of requests and may take up to a week or longer for a response. Just submit a request for the Vacuum diagram you want.We will provide you with the basic free Vacuum diagrams in an email that can be viewed, saved or printed for future use. Basic Automotive Vacuum diagrams are available free for domestic and Asian vehicles. Some European Vacuum diagrams are available also.

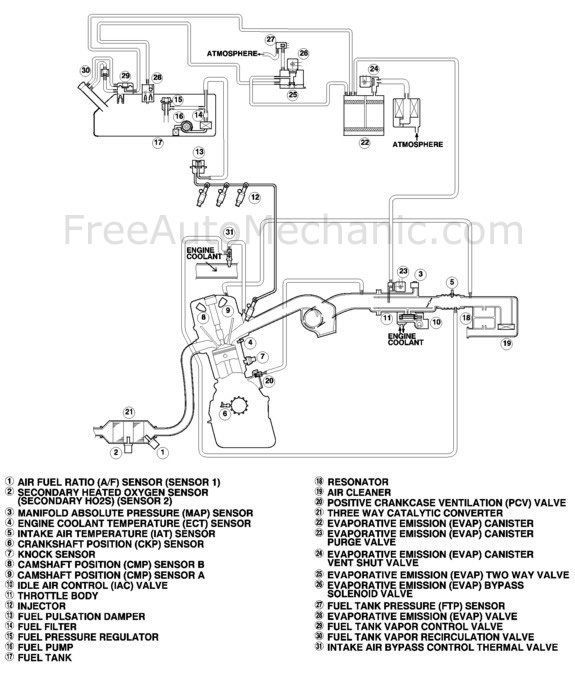

Once you get your Free Vacuum Diagrams, then what do you do with it. You still need to fix the problem that led you here in the first place right? There are many different ways to look at fixing a vacuum problem but we will stick with the easiest way. First , find the problem area on the Vacuum diagram. Highlight the individual area. Trace the Vacuum till you can see where a problem may have taken place. Eliminate each portion of the diagram in sections until you find the leak in the Vacuum. This makes knowing where to check connections easy with an automotive Vacuum diagram.

Example Request : need vacuum diagram for 2003 Honda Civic Ex Hatchback

Diagnosis and Testing: Visual Inspection

This is possibly the most critical step of diagnosis. A detailed examination of all connectors, wiring and vacuum hoses can often lead to a repair without further diagnosis. Performance of this step relies on the skill of the technician performing it; a careful inspector will check the undersides of hoses as well as the integrity of hard-to-reach hoses blocked by the air cleaner or other components. Wiring should be checked carefully for any sign of strain, burning, crimping or terminal pull-out from a connector.

Checking connectors at components or in harnesses is required; usually, pushing them together will reveal a loose fit. Pay particular attention to ground circuits, making sure they are not loose or corroded. Remember to inspect connectors and hose fittings at components not mounted on the engine, such as the evaporative canister or relays mounted on the fender aprons. Any component or wiring in the vicinity of a fluid leak or spillage should be given extra attention during inspection.

Additionally, inspect maintenance items such as belt condition and tension, battery charge and condition and the radiator cap carefully. Any of these very simple items may affect the system enough to set a fault.